tissue types

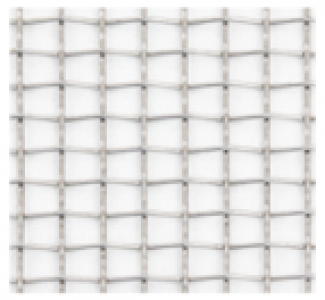

square mesh

- tighter grain boundaries

- small and medium grain sizes

- wire Ø 0.80 – 6.00 mm

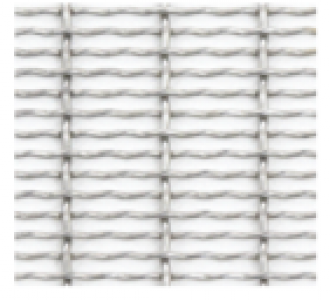

long mesh

- larger grain boundaries

- increased throughput

- small and medium grain sizes, wire Ø 0.80 – 6.00 mm

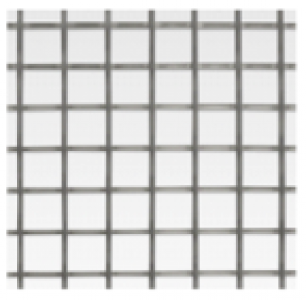

lead frame

- pre-screening of coarse and medium grain

- pressed smooth on one side

- wire Ø 7.00 – 12.50 mm

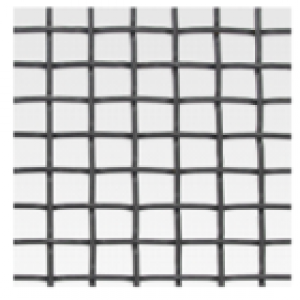

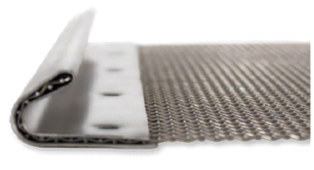

pressure welded frame

- Pre-screening of coarse and medium grain with increased loads and high wear

- individually welded crossing points

- highly wear-resistant manganese steel

- wire Ø 4.00 – 20.00 mm

long mesh pressure welded frame

- pre-screening of coarse and medium grain with increased throughput and high wear

- different mesh sizes of the sieve possible

- highly wear-resistant manganese steel, wire Ø 4.00 – 20.00 mm

harp tissue

- screening topsoil for small and medium grain sizes

- large open sieve area

- individual cross wire division, also with PU cast wires

- chromium-nickel wires

- wire Ø 1.00 – 3.50 mm

harp #2

- difficult-to-screen material

- small and medium grain sizes

- very good vibration effect and little sticking grain

- wire Ø 0.8 – 4.00 mm

harp #3

- screening sand, gravel and soil

- increased throughput

- largest open screen area with PU binding

- clayey and sticky screenings

- chrome-nickel steel wire Ø 0.8 – 4.00 mm

harp #4

- difficult-to-screen material

- small and medium grain sizes

- very good vibration effect and little sticking grain

- narrow grain boundaries

- Chromium-nickel wires, wire Ø 1.00 – 3.50 mm

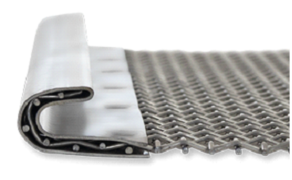

tension fold types

type #1

type #2

type #3

type #4

type #5

technical design

- different wire thicknesses up to 20.00 mm (e.g. pressure welded mesh)

- material made of highly wear-resistant manganese-alloyed special steel wire or chromium-nickel wires